[Development ] Intel.Parallel.Studio.XE.2017.Composer.Edition.for.Fortran

[Structural Analysis] RIBgeo v2017.1.4

[Biomedicine] Schrodinger.Suites.2017-1

[petroleum] Honeywell.UniSim.Design.R451.Build.20113

[Other CAD/CAM]

CimatronE v13.0 SP2 P2

[Siemens] SIEMENS.STAR-CCM+12.02.010-R8.Win64.&.Linux64

[MSC] MSC.Simufact.Forming.14.0.Win64

[Chemical] Intergraph PVElite 2017

[Other CFD] Tecplot.RS.2016.2.3.78146

[Other CFD] CEI.Ensight.10.2.1b.GOLD

[petroleum] Chemstations CHEMCAD Suite v7.1.2.9917

[Geographic Information] Golden Software Surfer v14.0.599

[ANSYS] FunctionBay.Multi-Body.Dynamics.Ansys.17.2.Win64

[Other CAD/CAM] MISSLER TOPSOLID V7.11

[Other CFD] FunctionBay.RecurDyn.V8R5

[Dassault CATIA ] CATIA DELMIA ENOVIA V5-6R2016 SP4 Update

[Siemens] Siemens.LMS.Samtech.TeaPipe.17.1.1138.for.Catia.V5R19-25

[Other CFD] Altair HyperWorks 2017.0.0.24 Suite Win64

[MENTOR] Mentor Graphics FloEFD 16.1.37 Suite

[Siemens] Siemens Tecnomatix Plant Simulation v13.0

[SolidWorks] 3DQuickPress v6.2.0

[Other EDA] IGI ParCAMwith EXT v8.8.2

[petroleum] Zeataline.PipeData.Pro.v12.0.20

[petroleum] DNV Phast v7.2.72.0

[SolidWorks] SolidCAM 2016 SP3 for SolidWorks 2012-2017

[SolidWorks] SolidWorks.2017.SP2.Premium

[Other CAD/CAM] AutoForm Plus.R7.0.1

[Other EDA] Altium Designer 17.0.10 Build 617

[MENTOR] Mentor Graphics HyperLynx v9.4.1

[MENTOR] Mentor Graphics FloTHERM XT v3.0

[ANSYS] ansys.HBM.nCode.13.0

[Autodesk] Autodesk Simulation Moldflow Adviser 2017.3

[Chemical] Process Systems Enterprise gPROMS v4.2

[Other EDA]

Motor-CAD v10.2.1

[Structural Analysis] Sismicad 12.9

[MENTOR] Mentor Graphics QuestaSim SE 10.4e

[Geological Prospecting ] ARANZ Geo Leapfrog Hydro v2.6.0

[ANSYS] ansys SpaceClaim 2017_ansys DesignSpark Mechanical 2017

[Other CAD/CAM] Mastercam 2017 v19.0.15109.0 Update3

[Other CAD/CAM] MecSoft VisualCADCAM 2017

[Siemens] TMG solvers for NX 9.0-11.0

[Geological Prospecting ] ARANZ.Geo.Leapfrog.Mining.v2.6.0

[Other CFD] Altair HyperForm Solista 14.0

[Other CFD] Altair Flux 12.2

[Other CAD/CAM] TEBIS V4.0 R3 for win64

[Geological Prospecting ] PaleoScan 2016

[petroleum] Honeywell PredictPipe v6.1

[Optics] OPTIS OptisWorks 2017

[Geological Prospecting ] ARANZ Geo Leapfrog v4.0.0

[petroleum] Kappa Ecrin v5.10.04

[Geographic Information] Schlumberger ECLIPSE 2016.2

[PTC] PTC Creo 2.0 M240

[SolidWorks] SolidWorks PCB 2016 SP5

[Geographic Information] Pixoneer PG-STEAMER V5.0

[Other EDA]

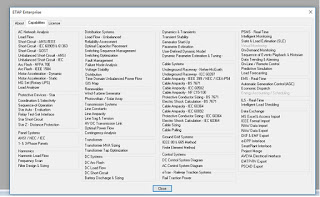

DSATools V15.0

[Other EDA] PSSE V34.0_Power_Transmission_System_Planning_Software

[Structural Analysis] CSI ETABS 2016 v16.0.3 build 1567

[SolidWorks] Geometric NestingWorks 2017 SP1.0 for solidworks

Contact:crackcad@gmail.com