The introduction of a volume-based modeling approach supports precise representation of geological complexity—to more accurately predict hydrocarbon accumulations. Geomechanical reconstruction validates interpretations in complex depositional environments. Further, geoscientists can now model 1D petroleum systems to determine charge maturity and risk.

The Petrel platform leverages advanced Schlumberger numerical simulators, which now include 3D geomechanical modeling of subsurface stresses, salt tectonics and wellbore stability, providing efficient 3D preproduction geomechanics and 4D modeling of producing fields. Reservoir engineering capabilities support complex well modeling to keep pace with completion design evolution. New production-analytics capabilities enable well performance analysis to diagnose production events and trends.

Customer Test Results

Petrel 2013 introduces a step-change in software beta test methodology. The Petrel platform architecture now tracks and audits beta testing, so that each of the broad range of capabilities is consistently and comprehensively tested. More than 30 oil and gas companies across the spectrum of majors, independents and national oil companies, as well as internal resources participated, culminating in more than 20 man-years of testing.

Powerful Productivity and Collaboration

The Studio* environment for Petrel allows E&P experts to find all relevant data, collaborate with peers and share best practices in the context of their workflow. Innovative indexing technology provides access to structured and unstructured data in Studio databases, as well as third-party applications and data sources.

The introduction of a volume-based modeling approach supports precise representation of geological complexity—to more accurately predict hydrocarbon accumulations. Geomechanical reconstruction validates interpretations in complex depositional environments. Further, geoscientists can now model 1D petroleum systems to determine charge maturity and risk.

The Petrel platform leverages advanced Schlumberger numerical simulators, which now include 3D geomechanical modeling of subsurface stresses, salt tectonics and wellbore stability, providing efficient 3D preproduction geomechanics and 4D modeling of producing fields. Reservoir engineering capabilities support complex well modeling to keep pace with completion design evolution. New production-analytics capabilities enable well performance analysis to diagnose production events and trends.

Customer Test Results

Petrel 2013 introduces a step-change in software beta test methodology. The Petrel platform architecture now tracks and audits beta testing, so that each of the broad range of capabilities is consistently and comprehensively tested. More than 30 oil and gas companies across the spectrum of majors, independents and national oil companies, as well as internal resources participated, culminating in more than 20 man-years of testing.

Powerful Productivity and Collaboration

The Studio* environment for Petrel allows E&P experts to find all relevant data, collaborate with peers and share best practices in the context of their workflow. Innovative indexing technology provides access to structured and unstructured data in Studio databases, as well as third-party applications and data sources.

2014-04-09

Schlumberger_Petrel_2013_crack

Schlumberger_Petrel_2013_crack

Advanced Science Addresses Key Technical Challenges

The Petrel 2013 platform delivers enhanced integration to address key challenges, for example accurate delineation of subsurface features in pre- and sub-salt reservoirs. The release brings improved salt interpretation workflows, augmented seismic imaging through pre-stack wide azimuth analysis, and improved links with Omega* seismic data processing software.

The introduction of a volume-based modeling approach supports precise representation of geological complexity—to more accurately predict hydrocarbon accumulations. Geomechanical reconstruction validates interpretations in complex depositional environments. Further, geoscientists can now model 1D petroleum systems to determine charge maturity and risk.

The Petrel platform leverages advanced Schlumberger numerical simulators, which now include 3D geomechanical modeling of subsurface stresses, salt tectonics and wellbore stability, providing efficient 3D preproduction geomechanics and 4D modeling of producing fields. Reservoir engineering capabilities support complex well modeling to keep pace with completion design evolution. New production-analytics capabilities enable well performance analysis to diagnose production events and trends.

Customer Test Results

Petrel 2013 introduces a step-change in software beta test methodology. The Petrel platform architecture now tracks and audits beta testing, so that each of the broad range of capabilities is consistently and comprehensively tested. More than 30 oil and gas companies across the spectrum of majors, independents and national oil companies, as well as internal resources participated, culminating in more than 20 man-years of testing.

Powerful Productivity and Collaboration

The Studio* environment for Petrel allows E&P experts to find all relevant data, collaborate with peers and share best practices in the context of their workflow. Innovative indexing technology provides access to structured and unstructured data in Studio databases, as well as third-party applications and data sources.

The introduction of a volume-based modeling approach supports precise representation of geological complexity—to more accurately predict hydrocarbon accumulations. Geomechanical reconstruction validates interpretations in complex depositional environments. Further, geoscientists can now model 1D petroleum systems to determine charge maturity and risk.

The Petrel platform leverages advanced Schlumberger numerical simulators, which now include 3D geomechanical modeling of subsurface stresses, salt tectonics and wellbore stability, providing efficient 3D preproduction geomechanics and 4D modeling of producing fields. Reservoir engineering capabilities support complex well modeling to keep pace with completion design evolution. New production-analytics capabilities enable well performance analysis to diagnose production events and trends.

Customer Test Results

Petrel 2013 introduces a step-change in software beta test methodology. The Petrel platform architecture now tracks and audits beta testing, so that each of the broad range of capabilities is consistently and comprehensively tested. More than 30 oil and gas companies across the spectrum of majors, independents and national oil companies, as well as internal resources participated, culminating in more than 20 man-years of testing.

Powerful Productivity and Collaboration

The Studio* environment for Petrel allows E&P experts to find all relevant data, collaborate with peers and share best practices in the context of their workflow. Innovative indexing technology provides access to structured and unstructured data in Studio databases, as well as third-party applications and data sources.

The introduction of a volume-based modeling approach supports precise representation of geological complexity—to more accurately predict hydrocarbon accumulations. Geomechanical reconstruction validates interpretations in complex depositional environments. Further, geoscientists can now model 1D petroleum systems to determine charge maturity and risk.

The Petrel platform leverages advanced Schlumberger numerical simulators, which now include 3D geomechanical modeling of subsurface stresses, salt tectonics and wellbore stability, providing efficient 3D preproduction geomechanics and 4D modeling of producing fields. Reservoir engineering capabilities support complex well modeling to keep pace with completion design evolution. New production-analytics capabilities enable well performance analysis to diagnose production events and trends.

Customer Test Results

Petrel 2013 introduces a step-change in software beta test methodology. The Petrel platform architecture now tracks and audits beta testing, so that each of the broad range of capabilities is consistently and comprehensively tested. More than 30 oil and gas companies across the spectrum of majors, independents and national oil companies, as well as internal resources participated, culminating in more than 20 man-years of testing.

Powerful Productivity and Collaboration

The Studio* environment for Petrel allows E&P experts to find all relevant data, collaborate with peers and share best practices in the context of their workflow. Innovative indexing technology provides access to structured and unstructured data in Studio databases, as well as third-party applications and data sources.

The introduction of a volume-based modeling approach supports precise representation of geological complexity—to more accurately predict hydrocarbon accumulations. Geomechanical reconstruction validates interpretations in complex depositional environments. Further, geoscientists can now model 1D petroleum systems to determine charge maturity and risk.

The Petrel platform leverages advanced Schlumberger numerical simulators, which now include 3D geomechanical modeling of subsurface stresses, salt tectonics and wellbore stability, providing efficient 3D preproduction geomechanics and 4D modeling of producing fields. Reservoir engineering capabilities support complex well modeling to keep pace with completion design evolution. New production-analytics capabilities enable well performance analysis to diagnose production events and trends.

Customer Test Results

Petrel 2013 introduces a step-change in software beta test methodology. The Petrel platform architecture now tracks and audits beta testing, so that each of the broad range of capabilities is consistently and comprehensively tested. More than 30 oil and gas companies across the spectrum of majors, independents and national oil companies, as well as internal resources participated, culminating in more than 20 man-years of testing.

Powerful Productivity and Collaboration

The Studio* environment for Petrel allows E&P experts to find all relevant data, collaborate with peers and share best practices in the context of their workflow. Innovative indexing technology provides access to structured and unstructured data in Studio databases, as well as third-party applications and data sources.

Agilent-Advanced-Design-System-(ADS)-2014-Crack

Agilent-Advanced-Design-System-(ADS)-2014-Crack

Key Features & Specifications

Advanced Design System (ADS) 2014 includes the following new products and improved capabilities:

Automatic EM/Circuit Simulation Setup & Partitioning

New Physical LVS with Device Recognition

New Wireless Verification Test Benches (LTE-A, LTE, 802.11ac)

Improved Layout Interconnect Design & Editing

Controlled Impedance Line Designer

Silicon RFIC Schematic Interoperability with Virtuoso

ADS Board Link – Next Generation PCB Integration Solution

Simulation Support for DynaFET model

Description

ADS 2014 is the next major step in delivering new capabilities, new technologies and more improvements to further realize a long-term vision to improving design productivity and efficiency through design flow integration.

Automatic EM/Circuit Simulation Setup & Partitioning

ADS’s popular Layout Lookalike capability lets the designer set up a circuit/EM co-simulation where the schematic models (e.g., SMT parts or active IC devices) are connected to a “lookalike” representation of the layout.

For cases where the device-count grows to dozens or even hundreds—ADS 2014 now offers a new automated EM/Circuit Simulation Setup capability resulting in substantial time savings and elimination of manual errors.

ADS 2014 Automatic EM/Circuit Simulation Setup & Partitioning

W2320EP/ET Advanced Layout (Physical LVS with Device Recognition)

Industry standard methodology for IC verification and foundry signoff.

Includes mode based on p-cells, without the need for a rules file.

P-cell mode works with module, multi-technology designs and pin nets for a robust module level LVS solution.

New Wireless Verification Test Benches (VTB)

Wireless VTBs provide circuit design verification solutions for the newest and most challenging multi-band, wide-bandwidth standards (LTE, LTE-A and 802.11ac) with a dramatically simplified user interface.

New VTBs and the underlying simulation technology are based on the SystemVue dataflow simulation technology and also allow system architects to develop custom VTBs for use by circuit designers in ADS.

Simplified VTBs offered at a significantly lower cost than Ptolemy-based Wireless Libraries.

Description

ADS 2014 is the next major step in delivering new capabilities, new technologies and more improvements to further realize a long-term vision to improving design productivity and efficiency through design flow integration.

Automatic EM/Circuit Simulation Setup & Partitioning

ADS’s popular Layout Lookalike capability lets the designer set up a circuit/EM co-simulation where the schematic models (e.g., SMT parts or active IC devices) are connected to a “lookalike” representation of the layout.

For cases where the device-count grows to dozens or even hundreds—ADS 2014 now offers a new automated EM/Circuit Simulation Setup capability resulting in substantial time savings and elimination of manual errors.

ADS 2014 Automatic EM/Circuit Simulation Setup & Partitioning

W2320EP/ET Advanced Layout (Physical LVS with Device Recognition)

Industry standard methodology for IC verification and foundry signoff.

Includes mode based on p-cells, without the need for a rules file.

P-cell mode works with module, multi-technology designs and pin nets for a robust module level LVS solution.

New Wireless Verification Test Benches (VTB)

Wireless VTBs provide circuit design verification solutions for the newest and most challenging multi-band, wide-bandwidth standards (LTE, LTE-A and 802.11ac) with a dramatically simplified user interface.

New VTBs and the underlying simulation technology are based on the SystemVue dataflow simulation technology and also allow system architects to develop custom VTBs for use by circuit designers in ADS.

Simplified VTBs offered at a significantly lower cost than Ptolemy-based Wireless Libraries.

Please contact : crackcad@gmail.com

Description

ADS 2014 is the next major step in delivering new capabilities, new technologies and more improvements to further realize a long-term vision to improving design productivity and efficiency through design flow integration.

Automatic EM/Circuit Simulation Setup & Partitioning

ADS’s popular Layout Lookalike capability lets the designer set up a circuit/EM co-simulation where the schematic models (e.g., SMT parts or active IC devices) are connected to a “lookalike” representation of the layout.

For cases where the device-count grows to dozens or even hundreds—ADS 2014 now offers a new automated EM/Circuit Simulation Setup capability resulting in substantial time savings and elimination of manual errors.

ADS 2014 Automatic EM/Circuit Simulation Setup & Partitioning

W2320EP/ET Advanced Layout (Physical LVS with Device Recognition)

Industry standard methodology for IC verification and foundry signoff.

Includes mode based on p-cells, without the need for a rules file.

P-cell mode works with module, multi-technology designs and pin nets for a robust module level LVS solution.

New Wireless Verification Test Benches (VTB)

Wireless VTBs provide circuit design verification solutions for the newest and most challenging multi-band, wide-bandwidth standards (LTE, LTE-A and 802.11ac) with a dramatically simplified user interface.

New VTBs and the underlying simulation technology are based on the SystemVue dataflow simulation technology and also allow system architects to develop custom VTBs for use by circuit designers in ADS.

Simplified VTBs offered at a significantly lower cost than Ptolemy-based Wireless Libraries.

Description

ADS 2014 is the next major step in delivering new capabilities, new technologies and more improvements to further realize a long-term vision to improving design productivity and efficiency through design flow integration.

Automatic EM/Circuit Simulation Setup & Partitioning

ADS’s popular Layout Lookalike capability lets the designer set up a circuit/EM co-simulation where the schematic models (e.g., SMT parts or active IC devices) are connected to a “lookalike” representation of the layout.

For cases where the device-count grows to dozens or even hundreds—ADS 2014 now offers a new automated EM/Circuit Simulation Setup capability resulting in substantial time savings and elimination of manual errors.

ADS 2014 Automatic EM/Circuit Simulation Setup & Partitioning

W2320EP/ET Advanced Layout (Physical LVS with Device Recognition)

Industry standard methodology for IC verification and foundry signoff.

Includes mode based on p-cells, without the need for a rules file.

P-cell mode works with module, multi-technology designs and pin nets for a robust module level LVS solution.

New Wireless Verification Test Benches (VTB)

Wireless VTBs provide circuit design verification solutions for the newest and most challenging multi-band, wide-bandwidth standards (LTE, LTE-A and 802.11ac) with a dramatically simplified user interface.

New VTBs and the underlying simulation technology are based on the SystemVue dataflow simulation technology and also allow system architects to develop custom VTBs for use by circuit designers in ADS.

Simplified VTBs offered at a significantly lower cost than Ptolemy-based Wireless Libraries.

Please contact : crackcad@gmail.com

JMAG-Designer-v12-download-tutorials

This is the high-speed, high-precision FEA software tool at the core of JMAG.

An intuitive interface and precise modeling technology with a wide variety of results displays are built in.

Multifaceted evaluation of various design ideas is made possible by freely manipulating geometry, material properties, and drive conditions.

High Speed Solver

Higher Precision Loss Calculation

Multiphysics

Magnetic Field Analysis/Centrifugal Force Calculation

Magnetic Field Analysis/ Thermal Equivalent Circuit Calculation

Thermal Analysis/Thermal Stress Calculation

New Framework for Coupled Analysis

Vibration Transient Analysis

Mesh Generation

Optimization

Results Analysis

Model-Based Development

Functions List

Geometry Modeling

Material Database / Material Modeling

Mesh Modeling

Results Evaluation

Solver

HPC

Optimization Ver.13

Automation / Scripts

Interface

On-Demand Information

JMAG-Designer-v12

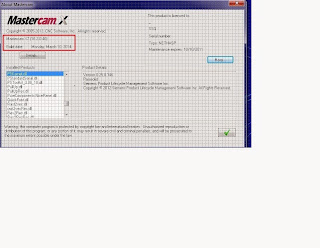

Mastercam_x7_MU2_16.2.0.40_crack_tutorial

Mastercam X7 does not allow you to save to a previous version Mastercam format. Use an alternate file

format if you must revert to an earlier version of Mastercam. IGES, STEP, and Parasolid are examples of

the available formats. Your geometry is saved with no toolpaths or solids history.

Using New Backplot in Mastercam Simulator

If you would like to use the new Backplot mode available in Mastercam Simulator by default, you can

make this change through the Mastercam Advanced Configuration dialog box.

1. Click Start, All Programs, Mastercam X7, Utilities, Advanced Configuration.

2. Select Mastercam X7 from the version drop-down at the top of the dialog box.

3. Select Backplot from the Mastercam Properties tree control.

4. Select Disable from the list next to the Backplot option.

Mastercam X7 Service Pack 2 includes many bug fixes, including the following list:

Category Description Bug Numbers

Code Expert Fixed an issue with Find and Replace D-05915

Code Expert Fixed an issue with posting 5-axis operations on systems

running localized Windows

D-06335

Mastercam Simulator Nesting toolpath operations with different tools used in

different operations will now display correctly

D-06073

Mastercam Simulator Fixed various issues with 5-axis toolpath simulation D-06168, D-05929

Mastercam Simulator

message

D-06086

Mastercam Simulator The toolpath and tool display of a surface finish toolpath

with a transformation operation will no longer be

corrupted when the holder is not defined

D-06524

Mill Toolpaths, 2D

Contour output incorrectly

D-05821

Mill Toolpaths, 3D HST Fixed an issue where the toolpath was not generated

correctly when using an engrave tool

D-05973

Mastercam X7 Service Pack 2 includes many bug fixes, including the following list:

Category Description Bug Numbers

Code Expert Fixed an issue with Find and Replace D-05915

Code Expert Fixed an issue with posting 5-axis operations on systems

running localized Windows

D-06335

Mastercam Simulator Nesting toolpath operations with different tools used in

different operations will now display correctly

D-06073

Mastercam Simulator Fixed various issues with 5-axis toolpath simulation D-06168, D-05929

Mastercam Simulator

message

D-06086

Mastercam Simulator The toolpath and tool display of a surface finish toolpath

with a transformation operation will no longer be

corrupted when the holder is not defined

D-06524

Mill Toolpaths, 2D

Contour output incorrectly

D-05821

Mill Toolpaths, 3D HST Fixed an issue where the toolpath was not generated

correctly when using an engrave tool

D-05973

Mastercam X7 Service Pack 2 includes many bug fixes, including the following list:

Category Description Bug Numbers

Code Expert Fixed an issue with Find and Replace D-05915

Code Expert Fixed an issue with posting 5-axis operations on systems

running localized Windows

D-06335

Mastercam Simulator Nesting toolpath operations with different tools used in

different operations will now display correctly

D-06073

Mastercam Simulator Fixed various issues with 5-axis toolpath simulation D-06168, D-05929

Mastercam Simulator

message

D-06086

Mastercam Simulator The toolpath and tool display of a surface finish toolpath

with a transformation operation will no longer be

corrupted when the holder is not defined

D-06524

Mill Toolpaths, 2D

Contour output incorrectly

D-05821

Mill Toolpaths, 3D HST Fixed an issue where the toolpath was not generated

correctly when using an engrave tool

D-05973

Mastercam X7 Service Pack 2 includes many bug fixes, including the following list:

Category Description Bug Numbers

Code Expert Fixed an issue with Find and Replace D-05915

Code Expert Fixed an issue with posting 5-axis operations on systems

running localized Windows

D-06335

Mastercam Simulator Nesting toolpath operations with different tools used in

different operations will now display correctly

D-06073

Mastercam Simulator Fixed various issues with 5-axis toolpath simulation D-06168, D-05929

Mastercam Simulator

message

D-06086

Mastercam Simulator The toolpath and tool display of a surface finish toolpath

with a transformation operation will no longer be

corrupted when the holder is not defined

D-06524

Mill Toolpaths, 2D

Contour output incorrectly

D-05821

Mill Toolpaths, 3D HST Fixed an issue where the toolpath was not generated

correctly when using an engrave tool

D-05973

OPTIS-SPEOS-CAA-V5-Based-V16.1-tutorial

This new version includes Photometric targets created in the sensor allowing for faster simulations enhancing users productivity.

Ergonomics of simulation settings and result analysis are improved thanks to geometry groups and local meshing.

SPEOS CAA V5 Based V16.0 OSD users will enjoy new functionality including Interactive Real-Time Photometric analysis during Optical design.

Freeform elements such as Curved Prisms on Optical Lenses or Light Guides are an amazing way to control light.

We really hope you will enjoy this new version of SPEOS CAA V5 Based !

In addition to the beam shape and source images, Optical Surface can now interactively display an approximated intensity distribution of the selected elements.

Therefore, designers immediately have the understanding of photometric behavior of the surface and thus the ability to adjust the shape parameters to interactively optimize the design.

Punctual source will be supported in a future version.

The free form type of Optical Surface feature has been enhanced to manage target distribution.

Users can now control light with better control with an easy to use interface.

Optical design can be adjusted to closely fit with targets without any light losses

Optical surface with circular grid and radial shift now has the possibility to add automatic sewing.

This operation is done in a couple of seconds instead of several human-days of hand work.

Automatic sewing is a great improvement for your productivity.

New option on Optical Lens feature.

In addition to Prism and Pillow, you can now select Pyramid prisms.

The end-customer will not see inside your transparent product.

Optical Shape Design

These elements are generated automatically in a few seconds compared to previously in several days when manually done.

ESPRIT-v2014-download-crack

Program any Machine Tool

The high-performance ESPRIT system offers powerful programming for any CNC machine tool. ESPRIT's full-spectrum functionality includes programming for 2-5 axis milling, 2-22 axis turning, 2-5 axis wire EDM, multitasking mill-turn machining, and B-axis machine tools. Streamline your operations with the powerful and flexible ESPRIT system, valued by CNC programmers for its extensive suite of machining cycles, comprehensive tool control, and capacity to fully support an entire shop.

Machine any Part Geometry

ESPRIT 2014 seamless CAD to CAM interface directly imports any native part model from any source, fully intact, with no need for programmers to edit or rebuild geometry. ESPRIT directly machines from any combination of geometries — solids, surfaces, wireframe, or STL — providing you with complete manufacturing flexibility. Starting with 100%complete and accurate part geometry eliminates nearly all of the difficulty in programming complicated parts and dramatically reduces programming time.

Universal Post Processing

ESPRIT 2014 universal post processor effortlessly creates the high-quality G-code you need to fully exploit your machine tool investment. With ESPRIT you get proven out-of-the-box operation with a complete library of pre-defined post processors. Additional factory-certified posts are available for many of the leading machine tool brands, and ESPRIT's open architecture allows you to easily adjust any post processor to suit your personal preferences and shopfloor requirements. ESPRIT's flawless G-code means you will spend more time cutting parts, giving you maximum machine utilization and optimal part quality at the lowest possible cost.

Dynamic Solid Simulation and Verification

ESPRIT 2014 fast, accurate, and reliable dynamic solid verification eliminates the need for expensive dry runs on the NC machine. Gain complete confidence in your machining process as you compare accurately rendered "as designed " versus "as machined" parts. High-performance, real-time simulation and comprehensive collision detection ensure that even the most complex of parts will be machined correctly the first time. ESPRIT gives you exhaustive verification of the part program simulated within a complete machining environment: machine tool, fixtures, clamps, stock, and workpiece. Minimize downtime, maximize manufacturing efficiency, and cut machining costs while gaining complete confidence in your machining processes with ESPRIT.

download

Subscribe to:

Posts (Atom)